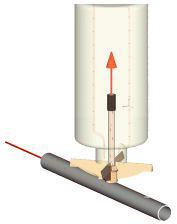

Direct injection cleaning

The 810 LX provides injection washing on one or two levels simultaneously, delivering the wash/rinse solutions into narrow-necked glassware to provide for efficient and effective cleaning. Low profile, rear manifold connections provide wash/rinse solution to the racks, maximizing usable rack surface, which is often reduced by common center manifold designs. 100% of the chamber volume is then available for an unbeaten washing capacity in this size/range of glassware washers.

Ease of Use

The 810 LX features microprocessor controls with 4 pre-set programs for chemistry glassware, bacteriology/virology (high temperature), stubborn stains (agar) and volumetric glassware (lower-temp). For other applications the 810 LX offers 16 additional programs that can be modified to fit any application. These custom programs offer the user the ability to easily adjust cycle parameters for program phases, temperatures, phase times and chemical dosing. The system control panel is user friendly with a 7 button keypad and 2 ½ inch LCD interface. Self-diagnostic software provides visual and audible alarms to quickly alert the user in the event of a malfunction, displaying the error and allowing the owner to avoid costly service calls.

Unbeaten cleaning and drying results

Lancer’s superior hydraulic design maximizes flow and pressure with a single, direct fluid path and no intermediate accessories. Additionally, racks are held in place by the door to ensure positive connection without the loss of pressure and flow that is common with other designs. Top and bottom spray arms provide thorough coverage for the interior and exterior of glassware. Water rinses are programmable for hot, cold and hot/cold DI water. These features allow for maximum use of the space within the chamber and ensure cleanliness. This design enhances full interchangeability of the racks between levels, providing further flexibility and reducing the number or racks needed.

Superior construction

The Lancer 810 LX washer is built to the highest standards. With AISI 304 L stainless steel and electronically welded chamber (under Argon protection), the unit is fully enclosed on all 6 sides to protect components and wiring. Maximum durability of the washer components ensures a long life span. Additionally, the 810 LX is insulated with synthetic rubber based, closed cell foam to guard against heat lost and reduce noise levels creating lower utility costs and a better user experience in the lab.

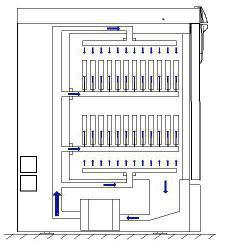

Inventory systems

Having the right rack or accessory to fit your cleaning application is key to ensuring cleanliness and increasing productivity. With this in mind, Lancer provides versatile rack systems to accommodate all types of glassware and laboratory items. These rack systems include a wide range of accessories with various configurations of sizes and quantities of jets or baskets to handle all types of glass and lab ware from bottles to pipettes. Racks can be interchanged between levels to achieve further flexibility.